I’m easily frustrated!

This week: I’m easily frustrated; Engineering solutions; Weather statistics;

I hate the week after the autumnal clock change. I’ve not slept well and the felines have been complaining because their feeding times (and mine) are all muxed ip!

This week has been another of those “single project” weeks, where almost the whole of my working day has been spent on the wood stove flue system. But more of that later.

Everything this week has reinforced what I mentioned last week, about never seeming to finish a project. Certainly, not finishing many projects within a single week!

In the middle of the week I received the final part and probably the most crucial part, for my new computer.

The postman delivered a solid state hard disc drive, or HDD, from the supplier in the Netherlands.

Over the years, HDD technology has improved in leaps and bounds. The capacity has increased whilst the size has got smaller.

More importantly, they have changed from having moving read/write heads to being “solid state” without any moving parts.

If you ever have the urge to open a HDD, which I strongly suggest you resist, this is what is inside.

The circular silver platens are where your data is stored and the triangular arm is the bit which moves and does the reading and writing of data.

There is other complex technology which moves everything with a hight level of accuracy, but that is about it.

But this 2025, so I wanted a “sold state” HDD which would run Windows 11. This is what came this week.

I need to copy the Windows 10 operating system over, to install it in the new computer and then upgrade the system to Windows 11.

To do this I bought an adapter. However as soon as I tried to connect the new HDD to the adapter, it wouldn’t fit.

It took quite a bit of reading to discover that my new HDD’s connector is an M-Key and the adapter unit is a B+M-Key. A very slightly different size with the key-hole in a different place.

I can’t do anything without the new HDD and I can’t copy my operating system until I get a different adapter – which I have now ordered.

It was cheaper to buy a new adapter than a new solid state HDD.

Looking at the sellers website, nowhere does it state the connector type, or offer the different types, so I was left frustrated and once again unable to complete a project…

I’m easily frustrated

As we move closer to the cold weather, I have been trying to finish the flue pipe for my wood stove.

Once again my buildings got in the way. To start with I couldn’t get the air radiator to seat properly on the top of the wood stove.

Either there was a gap at the bottom, between the flange and the top of the stove, or there was a gsp between the 90 bend and the new pipe where it goes through the wall.

I resorted to a level and immediately saw the problem.

The wall pipe is not level, it slopes down towards the outside, by 3/4 of a bubble on the level.

I hate doing it, but I resorted to using high temperature silicone sealant at both ends. At least I got everything so it would fit, albeit with a small gap, sealed with silicone, at both ends.

Of course, the only sealant I could get was ochre coloured, so now it neither matches the black wood stove, nor the cream air radiator, or the new white wall pipe.

At least I can see where I have used sealant.

Outside I realised I would have to dismantle the flue extractor fan. Last year when I serviced the fan, I replaced all the fixings with stainless steel. That made them easy to remove.

With the fan on the ground, I thoroughly serviced the whole unit. Then it was time for reassembly.

That did not go well! Fixing the base plate, it was proud of the frame by 4 cm. Nothing I could do would bridge the gap and without it being flush, I could not secure the fan.

Ordinarily I would use wood to fill the gap, but in an area which is subject to high temperatures, that solution is not an option.

I dismantled everything again and removed the wedge shaped smoke gasket which was inside the base of the fan.

Then I did a “dry assembly” on the ground with a piece of pipe. I discovered that there was now no restriction on the flue pipe so tried another install.

This time there was no gap. I reinstalled the smoke gasket to finish the job.

Engineering my own solutions

Identifying a problem is a necessary part of making repairs. Preventing the problem reoccurring is a necessary part of the solution.

The corrosion problem in my pipes is because they are in the cold air outside. All wood, even kiln dried logs, has moisture inside them. When the wood is burnt, this moisture exits the wood stove via the flue pipe.

When the flue pipe is cold, the moisture condenses on the inside, combines with acids and other elements which are products of combustion and over time corrodes the steel from the inside.

That is what has happened to my steel pipes.

I know that flue pipes should be insulated, especially when they are made of metal. So the answer to that problem is to insulate the pipe with rockwool.

Rockwool is made of mineral fibres. Slag from industrial sites is melted at very high temperature, then the liquid rock is spun to make fine fibres.

These are then woven into mats or blocks. They are fire resistant and have high thermal resistance and acoustic properties.

There are times here in Croatia when I just do not understand the thought processes!

You can buy pre-formed concrete block chimneys which are already insulated. However there is no equivalent for the standard brown 120 mm mild steel flues, which are sold in all DiY and builders merchants.

So if you identify that a concrete flue needs insulation, why not a steel flue?

Searching on line, they are readily available in many northern European countries, but not here…

I had some rockwool in one of my stores, however it is in 100 mm blocks which flex but do not bend.

Looking at the photographs on line of the commercial products, they are only 6cm thick AND they are cut, so that they bend easily into a circle.

After some thought and a little trial and error, I cut my rockwool lengthwise into three equal strips, each with a 45° edge. These I could then fit around the flue pipe.

I fastened them roughly into place with some reinforced tape. Then I started covering the rockwool with aluminium tape.

Rockwool is an awful material to work with. You need gloves and a mask because of the fibres. It is almost as bad as working with fibreglass matting!

Wrapping the rockwool was a lengthy exercise, done over three days. But I did get it all finished by lunch time on Saturday.

I remembered to leave a small access hatch, so at some point if I need to clean the inside of the flue, I can still get to the access point on the bend of the 90° steel pipe.

When I did a cost benefit analysis, the cost of the materials and the time exceeds the cost of a replacement pipe, by some margin.

I will be interested to see what if any effect this insulation has on the way the wood stove operates over the forthcoming winter…

Weather statistics

I came across this photo this week, which I took in 2023.

What surprised me was how many leaves were still on the Linden tree which is visible from my terrace (the tall tree in the background). I tried to recreate the photograph, but because trees around my home have grown, I couldn’t

Then I had a look at my Golden Virginia creeper, which I also photographed on 5th November last year.

This year, almost all the leaves have fallen. So my assessment that leaf fall has been a week to two weeks earlier than in previous years is about right.

Today (Saturday) being the 1st November, I downloaded the last data for my weather station from October and added it to the spreadsheet. This produces the charts which I put onto the Facebook local weather group that I run here.

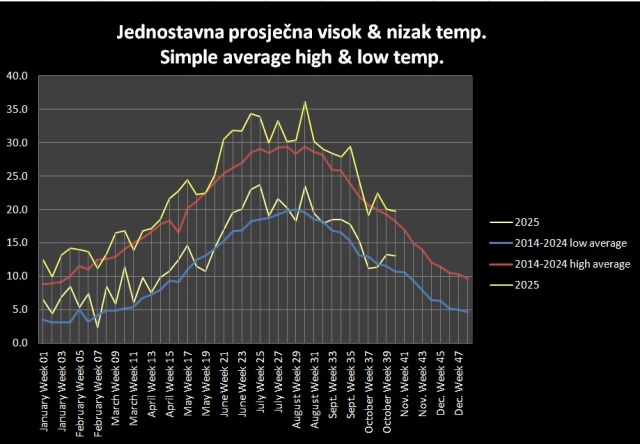

So the first 10 months of 2025 in three charts look like this:

The average high and low temperatures (in yellow) show that just three weeks out of 40 were below the average high temperature.

Four weeks were below the average low temperature.

32 weeks (80%) were above or well above the average. We are mirroring the rising temperatures reported around the world.

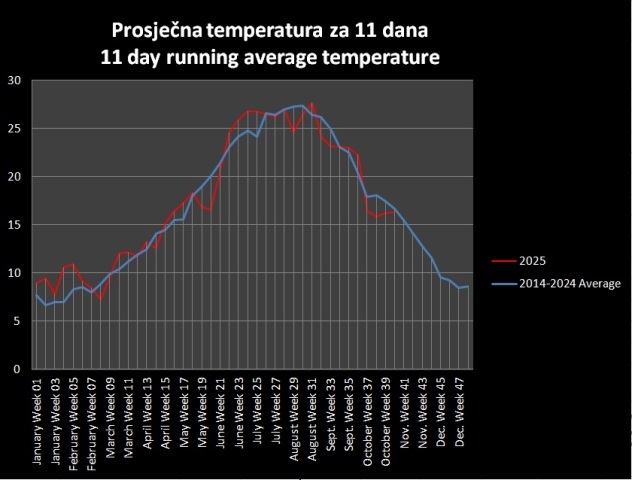

The 11 day running average is more nuanced and suggests that average temperatures are just marginally above the long term average.

The 11 day average is the one which I use to guide my planting and sowing. It is based on temperatures I record around my home and is barely affected by a single very hot day or a single cold night.

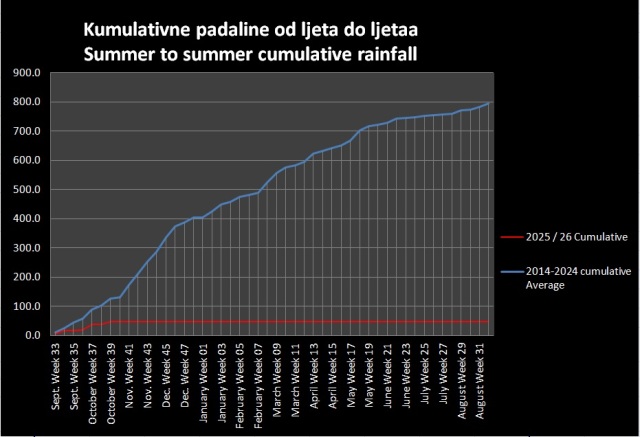

Coupled with the temperatures, the other data which most interests people on Otok Hvar is the amount of precipitation I record.

Because of the effect of the the highest point on the island, Sveti Nikola at 626 metres AMSL, which causes a rain shadow effect, I find there is significant differences between the rainfall I record here in Dol, and the amount recorded by other stations in Stari Grad and Vrboska.

Although I am only 5km from Stari Grad and 10km from Vrboska, there can be tens of millimetre difference.

Svete Nikola is immediately behind Dol and divides weather, especially storms, so I watch rain bypassing the village.

All this means that at week 40 we are 100mm or 100 litres/m² under the average. This is why everything is so dry.

A hot and dry summer has meant that leaf fall from deciduous plants and trees is about two weeks earlier than previously.

I really garden and plant from one year to the next because no one can say what the weather in 2026 and beyond will actually be like… NCG