Tee-shirt weather

This week: Planting time; Digging deep; Roof with a view;

We are at that tipping point in the spring weather. When the sun shines, it is lovely and warm. For the first time this year It has been warm enough to work outside without a NATO sweater. It is nice to be back to tee-shirt weather!

There is considerable heat in the sun at this time of year. As soon as the sun catches the wind covers on my orange and lemon trees in the morning, the steam rises as overnight dew evaporates.

But being the tipping point between seasons, it can still be cold. The weather can see-saw between winter and spring. Looking ahead for the next ten days, next weekend there may be a couple of nights when a light frost will be possible.

I’ve been busy with odd jobs this week. Doing things like trying to extract the roots of the Šipac tree that I cut down just before Christmas.

All the recent rain in Dol has saturated the ground. This makes any work involving treading on soils inadvisable. The soils are already compacted and that is without my size 42 boots walking all over everything and compacting it some more!

As spring advances, I did some structural alterations to the outdoor propagator that my neighbour Steve gave me last year.

The frame was a little short for the plastic cover, so I cut four more feet, double the height of the originals.

This additional height will both give a little more space below the bottom tray and also allow the plastic cover to fit more snugly.

With the frame now against the wall, I also added a ring, so I can firmly secure the propagator to stop the wind blowing it over.

Planting time

The effective last date for frost in Dol is the 14th February. The average low temperature for the first two weeks of February is 5ºC. The average for the second half of the month is 7ºC.

In my time here, the coldest early spring period I recorded was the last few days of February and the 1st of March 2018. Over three days there were overnight low temperatures of -3.3º and -4.1ºC.

However these are the extreme low temperatures. The daily night time average for the end of the month is between 2ºC and 5ºC with a daytime average of 10ºC.

Everywhere I look the plant and animal kingdoms think that spring is here. The Scarlet lily Beetles have emerged this week. A full two weeks earlier than previous years.

Some trees that I have been growing on in big pots need to go into the orchards. So this week I have been digging holes, or at least trying to!

With all the rain in January, my clay based soils are heavy and sticky. Now is not the time to be trying to work them, but I need to.

My courtyard base is sand and sandstone, which is very free draining. Perhaps this year I will be able to get it properly paved.

I have a columnar Shropshire Damson tree to go into the courtyard, as a fruiting and shade giving tree.

Damsons are a traditional English variety of clingstone plum.

When growing wild in the hedgerows they are often called Sloes. In times past the fruit was gathered to make Sloe Gin.

Often straight from the tree the fruit has an astringent taste.

But once cooked and served either in a pie, as stewed fruit or over wintered in Kilner jars, the fruit’s flavour develops.

The County of Shropshire is thought of as part of the English Midlands and borders Wales. However the Shropshire Damson is a north of England variety of Damson.

It is another of my experimental plantings.

Damsons are a particular favourite fruit of mine with their intense and exquisite flavour.

‘Wild’ plums can be seen around Dol, alongside paths and in some hedgerows.

However they seem to be cultivated trees that have “escaped” as opposed to the hedgerow trees that are seen in England.

Th Shropshire Damson variety was very carefully chosen for planting here in Dol.

I needed a tree that is self fertile, so not relying on another nearby to produce fruit.

The tree also needs to be able to withstand the summer heat and does not require a lot of winter cooling.

Most fruit trees need to have a certain number of hours in winter, when the temperature is below 5º to 7ºC. This is what horticulturists refer to as a chilling requirement.

In Dol, where there is really only a six to eight week period of winter from early December to mid February, I needs trees that require only a small amount of chilling.

The one area of concern that I have is the tree’s need for a deep rich soil.

I hope that because I have grown this sapling on from bare rooted stock, in a large pot, if I then put it in a large hole in the sandstone yard, it will quickly establish.

One of the things that I learnt in Abu Dhabi, is that the yellow sands of the desert are extremely fertile.

The yellow sand was brought in huge quantities to coastal areas because the local coastal Sabkha (AR: سبخة) is such a poor growing medium.

Digging deep

The open courtyard is funnel shaped, running east-west and is ten by seven meters.

The longest straight edge is 10 meters, along the frontage of the large Konoba. On the south side, the courtyard has several nooks, crannies’ and corners.

I decided to plant the tree in the corner next to the steps. This is a protected area where there will be no conflict between vehicle and foot traffic and a tree.

Another requirement of Damsons is plenty of sun. As the tree grows to its full height of about five meters, so it will receive more sun. In summer it will get about eight hours, but as it establishes, somewhat less.

This means it will be protected from the heat of the day. In winter it will be in a cool sink, so will get the chilling it requires. At least that is my theory.

Although the floor of the courtyard is soft sandstone, I still needed my big breaking hammer. This easily smashed the soft rock which I could then easily remove by hand.

The pure yellow sand between was easy to just shovel out.

I have gone down 40 cm below the finished level of the courtyard and the width of the planting pit is 50 x 50 cm.

I used the breaking hammer, which has a 30 cm long blade, to go down vertically in the floor of the pit to make sure there is good drainage at the bottom.

The expert’s advice is that Damsons can be grown in large pots on a patio.

So this pit is in essence, a very large porous pot. There is the space where the tree can extend its roots out into the sandstone as it likes.

There is also a fallpipe from the patio rain trap, so it will get plenty of moisture as well.

I backfilled the pit with a mixture of soil based compost, rich soil from the fold yard and sand.

With the help of a spirit level, I marked behind the tree the finished height of the courtyard (that is when it gets finished!).

I then did a trial positioning with the tree, still in its pot, to make sure the graft join on the trunk would be above the finished courtyard level.

I had to pack a bit more soil in.

Breaking the tree out of the pot was not too hard.

The pot was plastic and had split from top to bottom is several places. So rather than destroy the soil around the root ball by pulling, I was able to split the plastic pot with my fingers.

This allowed me to slide the tree and soil out in one piece and into place.

I moved more of the soil and sand mixture around the tree to support it and hold it in place. Everything was tamped firmly into place with a hand tamper that I have.

The last job was to build a small wall on the two open sides to retain the soil.

When I can get to the mainland, I will buy some proper edging pieces, which will be fixed in place on a bed of concrete.

You need something to hold the stone sets in place. If there is nothing holding the sets, the movement of vehicles in and out of the court yard will splay the stones.

Finally, I filled in around the tree and added a longer length of pipe to the fallpipe. I fitted an upturned end, so rain water will come out slowly and not wash the soil away.

I need to train the shoots and then I want to watch the buds burst. During the spring and summer I’ll nurse the tree through it’s first year, while it establishes.

I will be watching in future years to see when the first Damson blossom will appear.

Roof with a view

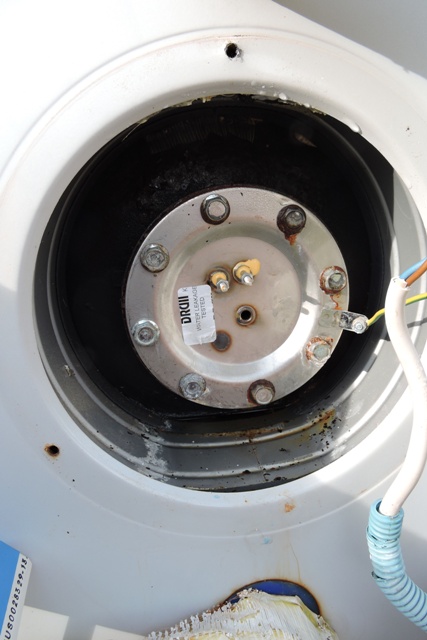

Just after Christmas I discovered that inside the electrical cover on my solar water tank, the gasket had a weeping leak (blog 2052).

I duly ordered the parts from the manufacturer in Italy ten days ago.

On Thursday the postman delivered the box of spares.

In the box there was a set of stainless steel bolts, two new gaskets and two new magnesium anodes.

I tend now to order two of what ever I need, within reason of course, one to use and one “spare” to go on the workshop shelf.

Having something “on the shelf” means that the next time there is a problem, there will be no delay in fixing it!

A check of the weather showed that Friday would be cloudy all day.

This was an advantage because it meant I needn’t cover the solar tubes up while the tank is empty, so there was one less job to do.

It is my “work smarter” ethos coming to the fore again!

Straight after breakfast on Friday morning I gathered together the tools I would need and shinned up my ladder onto the roof.

It really was a perfect day for working. With an air temperature of 14ºC, it was very pleasant being up on the roof. And with good visibility, I had a roof with a view of Stari Grad, the Agar and Brač.

The only awkward part was getting a small ring spanner behind the flange plate, to hold the rusty nuts while I undid the bolts.

Using a ratchet socket I could undo the bolts quickly and one handed.

Surprisingly, I had no difficulty undoing any of the eight bolts, despite a little corrosion on some of them

Withdrawing the flange, I saw there was an immediate problem. There was a sodden mass of calcium limescale, thickly encrusted all around the immersion heater element and the anode.

It was not difficult to carefully break away the calcium deposit with my fingers.

The tap water here is as hard as any I have experienced anywhere. The level of dissolved deposits and impurities justifies my water filtration system in the kitchen for drinking water.

I would have liked to have installed a water softener but going back to when I was updating the pipework from the rising main, I couldn’t find anywhere here where I could get the salt for the unit.

So whilst I could have bought a softening unit in the UK and had it shipped out, if I couldn’t replenish the salt, there really was not much point.

As an alternative I bought and installed an electronic softener with a wire coil. This electric coil is wrapped around the rising main.

When power is applied, the coil is said to create an electric field, disrupting the formation of limescale. But looking at the deposit, it would seem to be useless.

Using commercial descaler, I left all the various parts to soak while I cleaned out the inside of the tank by hand.

A small quantity of calcium had fallen off and had settled near the flange. This was within an arm’s reach inside the now empty tank.

I scraped away the last remnants of the calcium before using Solvol metal polish on all the faces. This meant that I had completely deposit free and polished metal surfaces to face the rubber gasket.

With a new anode screwed into place, the whole flange and imersion heat now looks as good as new.

For good measure I sprayed silicone lubricant onto the metal faces and the rubber gasket before I fitted the new bolts.

While I was tightening up the bolts, I also added some medium grease on each thread.

I turned the water back on and refilled the tank with 300 litres. With a mains pressure of 7 BAR and 5 BAR set on the tank’s pressure regulator I did a final check for leaks, made the electrical connections and replaced the cover.

There were no drips visible anywhere, so not a bad days work! NCG

2 Responses

Andy Robby

My mum used to make damson gin. I found two bottles dated 2004 when she died and it has become tradition to have a glass of it every Christmas morning!…. I reckon I’ve only got about 2 glasses left so may have to make my own!…. We have a young damson tree but it seems loath to produce fruit….. However there is one down the street which does… So a darkness visit may be on the cards!

mike speakman

I too have tried those electrical water softeners. No effect at all.