Ready, steady, PLANT!

This week: Polytunnel adjustments; A bit of fixing; The Green Comet; Ready, steady, PLANT; Treading carefully;

I am watching the weather very closely at the moment.

There is another cold snap being forecast as a Polar Vortex brings the jet stream south over Europe and with it some bitterly cold air.

With a biting north wind and clear skies, there is the potential for some frost, especially tonight and tomorrow.

Of more immediate interest though is a red warning for damaging winds tonight and tomorrow.

I added some securing rings when I was building the polytunnel and this morning I could be found fixing some nylon line as an added measure of security for the roofing panels.

Because the roof is now fixed differently, I don’t anticipate any more problems with panels lifting, but it is better to be safe than sorry.

It does feel cold today because of the strong and gusty wind. So much so that I lit the wood stove at 3pm. Recently I have not needed a fire until after tea.

It is just as well that I have had a delivery of rough, used timber this week.

This is builders waste, however it is dry, burns well and gives off a lot of heat too. It does burn quickly, but this one and a bit cubic meters will last me to the end of this winter’s burn season.

Polytunnel adjustments

As I was working inside the Polytunnel, in a tee shirt because it was warm in the sun, I felt a really cold draught coming through the gap between the frame and the uneven stone wall.

Stone being natural and without straight faces, means there there were a lot of gaps. The frame fits the wall where it touches, which is far from everywhere.

I also realised that my idea of leaving a vent gap to allow rain falling on the roof to fall through, was also letting hot air out.

So I reached for the “Go-to” product here, for all eventualities… expanding foam.

It didn’t take too long to inject foam into all the gaps and then let it expand to seal them.

There was a significant and immediate increase in the inside temperature. There was a further increase when I blocked the vents in the roof with Rockwool.

Rockwool will still let rain through, but will insulate and prevent hot air escaping too.

This has meant that this week the inside temperature has climbed steadily when the sun has shone, from 22ºC at the start of the week to over 30ºC by the end.

It is very humid inside at the moment which is a concern, because warmth combined with humidity allows things like Grey Mould, Botrytis cinerea, to thrive in greenhouses.

It is going to take me a while to really understand how to use the Polytunnel, to get all of its advantages.

Because the winter has been wet, and the soil was uncovered, it will take a few weeks for it to really dry out inside and for the humidity level to drop from the current 95%.

A bit of fixing

Sometimes one of the cheapest pieces of equipment gets the most use, AND last the longest.

I have a thirty plus year old “workmate”. This is one of those small, highly portable folding work benches which can be used to support whatever I am working on at the time.

However while I was building the stairs in the Konoba, one of the top plates broke in two.

It is hardly surprising because it is only made of fibreboard, so it has little integral strength.

But when you don’t have a favourite tool or piece of equipment, however old, however tatty, you still miss it.

Using an offcut from the wood I am using to build the staircase, I made two new and significantly more substantial top plates.

First I had to remove the rusty screws which held the old fibreboard plates in place. Then I greased the worm screw and the sliders, before carefully marking where the new plates would fit.

It has never seen grease since I got it.

I pre-drilled pilot holes and used longer SPAX TorkX screws to fit the plates into place.

At the same time I adjusted the spacing so the “Workmate” can hold larger pieces of timber between the plates.

With everything secured, It was time to start using my “Workmate” again.

It should last me for at least another 30 years now….

The Green Comet

If you looked up in the northern sky this week and glimpsed the Green Comet, you were lucky.

With the snappy name C/2022 E3 ZTF, the last time this comet was seen was during the Stone Age. If you missed it this week, hang around and it will be back again in another 50,000 years.

It was closest to Earth on Wednesday evening. But sadly here in Dol we had cloud, so although I was outside looking, I didn’t see anything more than the almost full moon.

There have been a number of really good photographs posted on-line though.

Ready, steady, PLANT

I decided that this week would be a good week to try some early plantings of seeds.

My heated propagator has been on in the greenhouse since before Christmas because I have some tender plants in there which I want to keep warm.

The thermostat has been set to 15ºC, so not excessively high, but just enough to keep things ticking over.

I filled some polystyrene plugs with potting soil, suitably moistened and put them into the propagator to warm up.

There is a school of thought which says that you should always soak seeds in warm water before planting. And that is not just those seeds where it is recommended on the packet.

Most certainly the soil temperature has great influence on the germination of seeds. Nothing (except turnips) likes growing in cold and damp conditions.

Vast amounts of research has been done into the ideal growing temperatures for tomatoes. They germinate best in a soil temperature over 10ºC, and grow best when the air temperature is over 18ºC.

So I was disappointed when I felt the soil on Wednesday and it felt cold and sticky.

This was easily solved by moistening the soil in the polystyrene with hot water from the kettle before I planted the seeds, on the 1st February.

I have started eight strips, four with different varieties of tomatoes and four with peppers. I will be watching closely to see what happens.

Meanwhile in the Polytunnel, I weeded an area towards the front and raked it clear of stones. After a couple of days sunshine to warm the soil, I planted some spring Onions and some lettuce.

It is getting hotter in the Polytunnel every day, with temperatures reaching 30ºC after the work I did this week to eliminate draughts.

The air heats the soil and the walls, which then release the heat after the sun sets, keeping the inside frost free.

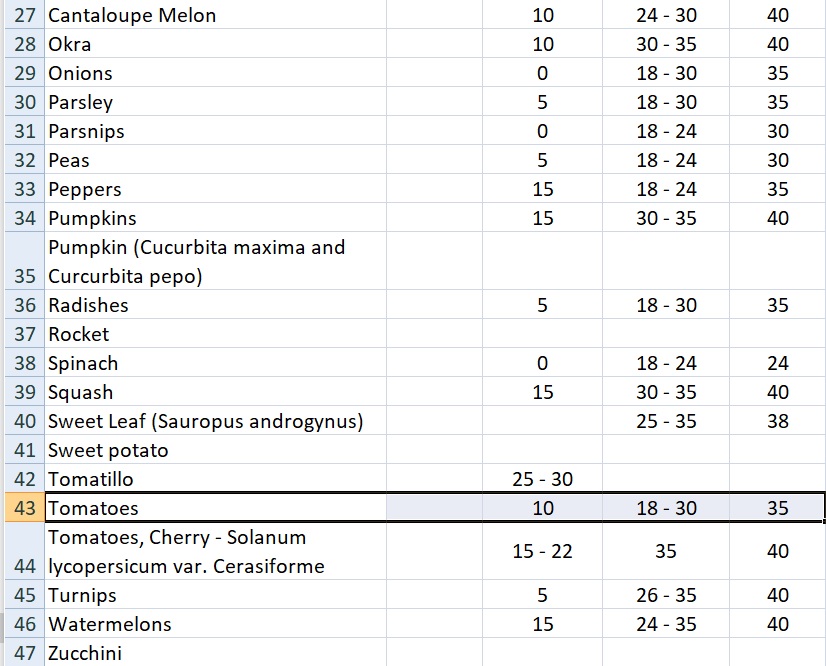

Using available on-line research, I have developed a spreadsheet with the minimum soil temperature, ideal air temperature for growth and maximum air temp for the seeds I plant.

This saves me trying to remember every variation for every variety of seed.

Treading carefully

In between the gardening this week, I have continued work on the Konoba stairs.

I made and assembled the third and final winder for the stairs and glued the two halves together.

I also cut some more pieces of timber to act as supports for the winders.

Each piece has to be individually planed and cleaned, cut square, then cut to size. When it is finished the pieces need the decorative edgeds to be made with the Palm Router.

After all that is said and done, each piece receives two coats of Sadolin treatment, with a sanding down between coats. This is to seal the wood and protect against insect attack.

It has been slow and fiddley work with little visible building progress. However that will change next week when everything is dry.

I was also looking at the height and angles for the bannister rail and also thinking about the floor above.

Way back in 2017 when I was levelling and insulating the floor above the Konoba, I stopped at the door because I didn’t know where the stairs would actually appear in the hall.

I now know where the stairs join the first floor level. Before I build the final steps and add the newel posts, I need to have the upstairs floor level as well.

All in all, I still have another couple of weeks work I think, before everything is finished. NCG

2 Responses

Mike & Linda, Oregon

Great work and skills. Thanks for the continued updates.

Marcy

My goodness, you are making amazing progress on all fronts. I’m excited to hear your evaluation of the progress in the polytunnel and the hothouse. Things will be growing soon. Those stairs have fascinated me from the very beginning.

It’s still under 60F here. Having an open house today to show the house and get this sell going. I can hardly wait to get to CA.

Have a great week and thank you as always for sharing. Marcy