Just two centimetres

This week: Summer Cooling; Building the infrastructure; Just two centimetres; A sting in the tail; Innovation in Action;

It remains hot here in Dol. Not as hot as some parts of Europe, because we are on the very edge of the latest “Heat dome”, which is affecting much of the continent.

I’ve been walking the olive groves this week and everything under foot is green. The rain in August has really kept the grasses and weeds alive.

However in my orchards, I am back to irrigating the newly planted trees and shrubs to make sure they survive until the next rains come.

The nights are drawing in and we are only just over a week away from the northern Autumnal equinox.

Mornings are simply beautiful.

The quality of the light is perfect for photography and the air has a delicious coolness, with the scent of the flavours of Autumn.

These are Rosemary flowers which line several of my garden paths. As you brush past them, their scent clings to your clothes and skin.

So many of the herbs we take for granted originate in the Mediterranean basin. They were spread across Europe by the Romans during their empire.

In later centuries, the European explorers and colonisers took the herbs from home with them, to plant in far off lands.

When they returned, they of course brought “new” herbs which they had discovered during their travels. These now grow side by side with the originals.

Summer cooling

My kitchen is compact (read small), being shoe-horned into space in what was probably once a pig sty.

All the units are from IKEA and came with me as flat-packs from Abu Dhabi.

The same goes for the appliances. Everything came from Abu Dhabi in the container, and the units fit around them.

The room is an irregular quadrilateral, and is very much a functional working area with no spare space.

It has a Velux window in the roof, making it feel light and larger than the space actually is, however there is neither heating nor cooling.

I decided I was going to extend the central heating because over the years, my idea that the heat from the wood stove in the dining room would transfer between the rooms didn’t work.

In summer, with three outside walls and three windows, it gets a tad on the warm side. This means that the under-the-counter refrigerator works overtime.

This year the ice box has been defrosting itself, usually at night, and water has been running out of the bottom of the fridge onto the floor tiles.

From there it has met the bottom of the unit end wall, which has absorbed the water and being fibreboard has now failed.

At ten years old the fridge is not the most energy efficient or economical so I decided that it would be a good idea to replace it.

One other complication is that the fridge door hinge is on the right side, and cannot be changed. I need a door with hinges on the left!

It has taken a lot of searching on-line to find an economical fridge, without an ice box, because I have a chest freezer in the utility room, which is economical AND has a reversible door.

I did find one and the new appliance was delivered on Tuesday afternoon.

Building the infrastructure

Anticipating the delivery, I removed the cabinet end wall and cut off the failed fibreboard section. I also needed to build a new base for the end wall.

Hunting through my wood offcuts box, I found a piece of wood, which when split into two would be the right length. However it was going to need some preparation before it was ready for use.

The first job was to cut the wood down the centre with my table saw.

The weather has been perfect this week for working outside in the courtyard, so I moved my tools out into the fresh air.

Next I faced the ends and using pegs and glue, joined them together.

After 24 hours in frame clamps to let the glue set, I ran the now single length of timber through the thicknesser to get everything square.

Work was then paused waiting for the new appliance to come, but this gave me time to treat the wood with clear varnish.

Once I am sure of the dimensions and clearance, I will rout a channel in the top to take the end panel and then fix everything into place.

On the bottom I will add aluminium runners, so the wood will not be in contact with the tiles, should the new fridge also leak moisture out at any time.

“Once bitten, twice shy” as the old saying goes.

I already have the radiator in stock, even if I can’t get to install the copper pipe work under the floor just yet.

Just two centimetres

I make a habit of measuring three times and cutting once.

It is so much easier to cut a little bit off, than it is to add a little bit onto something, if you cut it wrongly.

So when I opened the box with the new refridgerator, I immediately thought it looked bigger than the one I have. I measured it and it was 55cm wide.

Measuring the exisiting fridge, it is 50 cm wide and the gap is 53cm wide.

Looking again at the the online specification and it says 54cm wide. I also looked at my notes and I had correctly recorded the gap and the size of the existing machine.

I do vaguely recall that when I ordered the new appliance, I thought it was slightly larger, but I thought it would fit.

Well we all know what “thought” did!

This means that I need to move a single pedestal unit by a couple of centimeters, so it will fit.

However as the weather is beautiful at the moment – hot and sunny, I think I will leave the remodelling for week or two, when the weather is not condusive to working outside!

That will teach me to be more careful!

A sting in the tail

I’ve been removing the polycarbonate ribbed sheeting over the walkway between two of my buildings. That is until I discovered a Paper Wasp nest, Polistes gallicus, hidden in one corner.

I like wasps (except when they sting me) and they are definitely a gardener friend.

Gardens Illustrated produced a really useful guide recently about why you want to keep them in your garden.

Paper wasps in particular feed their young on small caterpillars, so they are a very effective pest control.

As I was staring at the wasps nest, one flew straight at my face and stung me on my lip. I have Anthisan cream always ready so applied some.

It wasn’t an attack, I think I just surprised the wasp as it flew out of the nest.

This meant that I had to wait until early morning, before sunrise, when it is cool and the wasps are lethargic to undo and move the sheet.

I have moved it out of the way while I work on the new roof beams, but not so far that I can’t replace it again, when I have finished.

Innovation in action

When I got up close to the corrugated Polycarbonate sheeting, I discovered that the specialist fittings I used to install it three years ago have been damaged by the strong UV we experience in Dol.

These are three part fittings. A stainless steel screw, a plastic spacer and a plastic cup and cap to protect the screw head.

The plastic has hardened and cracked, although it has still protected the screw head underneath.

There are a lot of them and they will need to be replaced before I put the sheets back in place.

This type of fixing is the standard fitting method in the UK, for corrugated roofing sheets. However looking on line, it seems they are only used in the UK.

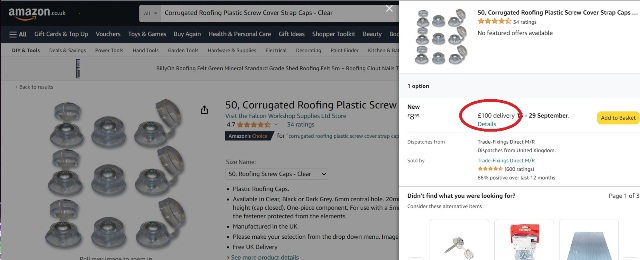

In the rest of Europe different, larger screw fittings are used. What I wasn’t prepared for was the price for sending a packet of 50 cups and caps to Croatia.

This is the result of Brexit. However I refuse to be held hostage to exorbitant prices like these for delivery.

I found and alternative supplier, who will deliver a bag of 100 by courier for €32. They should be here next week. That was the cheapest I could find.

Meanwhile, I cut the first two 5 x 8 beams I bought last week.

The middle one touches at both ends! You can now see why rain water was pooling in the middle of the roof.

I will cut some blocks to support the new beam, rather than trying to make it fit the curve.

Hanging on the walls of my workshop, I have a range of spirit levels, for different purposes. However the longest is 2 metres in length.

You can buy longer levels, but they are expensive and I need one only just occasionally. I have a laser level which usually works, but for the roof, it is not going to.

To make sure that I have a constant fall in the roof sheets when I replace them on the new beams, I joined two levels together with clamps.

I can now span the 3 metre roof with ease.

Once again it is Saturday lunch time, so work stops for the day. It is also extremely hot working in the mid day sun.

If you were able to look at images from one of the military high resolution satellites, you will probably find me up on the roof, early tomorrow morning, just as the sun is rising…. NCG